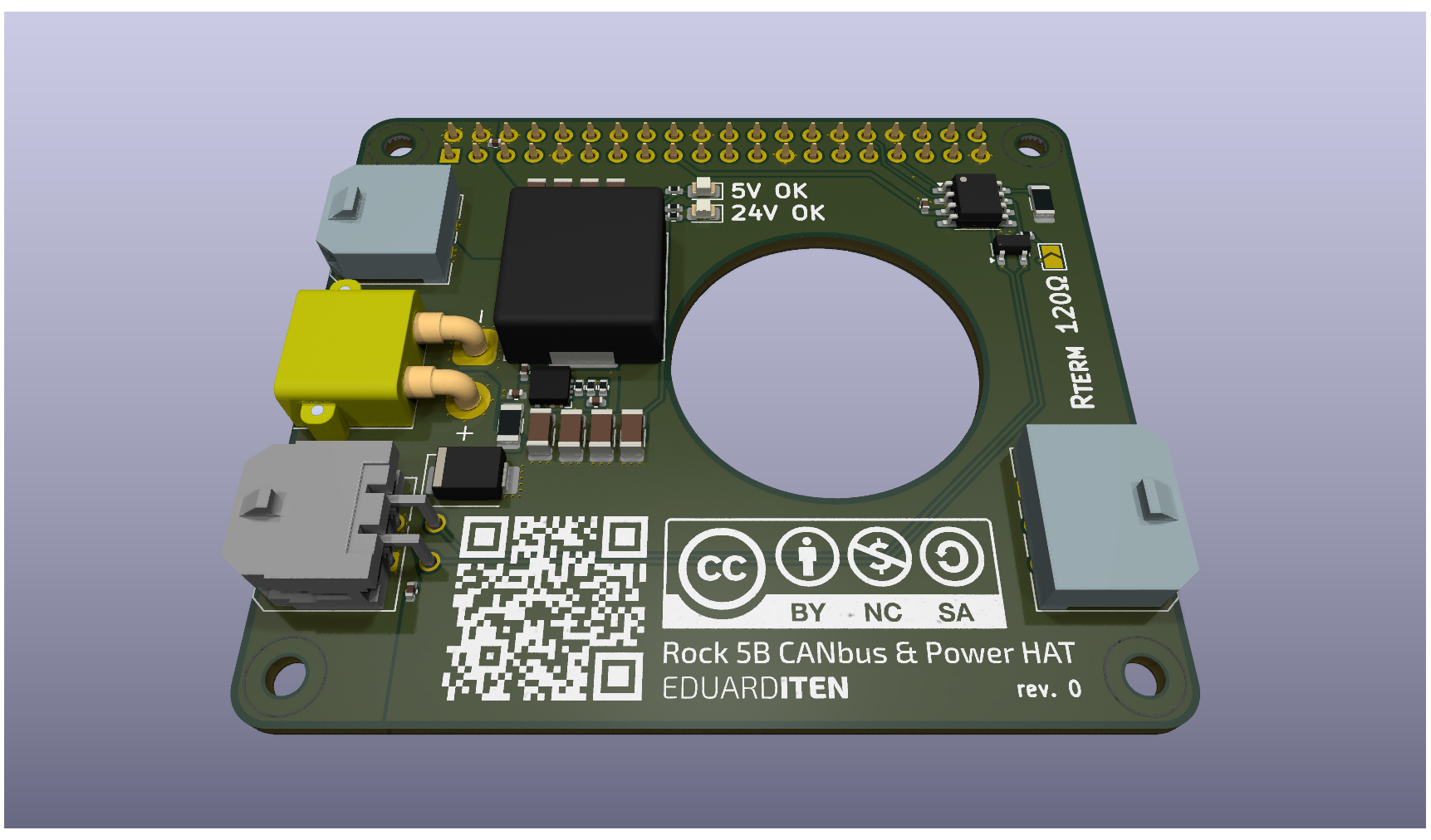

ROCK 5B High-Power CAN-Bus & Power HAT ("The Beast")

Table of Contents

- ROCK 5B High-Power CAN-Bus & Power HAT ("The Beast")

About the Project

This HAT was developed to turn the Radxa Rock 5B into the ultimate control center for high-performance laser plotters and 3D printers (Klipper). It addresses the specific weaknesses of standard solutions:

- Stable Power Supply: Delivers massive 5.2V/6A for the SBC and peripheral USB-C touchscreens.

- Native CAN Performance: Uses the integrated CAN controller of the RK3588 instead of slow SPI bridges.

- Thermal Management: A special "donut" design allows the CPU fan to draw fresh air through the PCB.

Features & Technical Specifications

⚡ Power Distribution (Split-Path Architecture)

The board separates power paths for maximum safety and performance:

- Input: 24V DC via reverse-polarity protected XT30 (High Current) connector.

- High-Power Path (Laser/Toolhead):

- Massive 3-layer copper connection.

- Direct 24V passthrough to toolhead (up to 120W+ possible, depending on power supply).

- Protected by SMBJ24A TVS diode against inductive voltage spikes (Back-EMF).

- Logic Path (SBC & Display):

- Protected by 2A Fast fuse (Littelfuse 0466 series, 63V rating).

- DC/DC Converter: TI TPS56637 Synchronous Buck Converter.

- Output: 5.2V (compensates for voltage drop on cables) at up to 6A.

🚀 Native CAN-Bus

- No USB adapters or SPI chips (MCP2515) required.

- Uses the native CAN1 Controller of the RK3588 (Pins 32/33).

- Transceiver: TI SN65HVD230 (3.3V Logic).

- ESD Protection: NUP2105L diode on data lines.

- Termination: 120Ω termination resistor switchable via solder jumper (JP1).

🔌 Poka-Yoke Connectors

Uses Molex Micro-Fit 3.0 with different pin counts to physically prevent fatal miswiring (e.g., 24V to 5V input).

| Port | Type | Pins | Description |

|---|---|---|---|

| 24V IN | XT30 | 2 | Main input from power supply. |

| TOOLHEAD | Micro-Fit | 2x2 (4-Pin) | 24V High-Current + CAN data to laser/print head. |

| CONTROLLER | Micro-Fit | 1x3 (3-Pin) | Pure data connection to MCU mainboard (e.g., Spider). |

| MONITOR | Micro-Fit | 1x4 (4-Pin) | 2x 5.2V / 2x GND for powering external displays. |

Pinout

J102 - TOOLHEAD (4-Pin Micro-Fit Square)

This is where the laser or print head is connected.

- 24V (Unfused, High Power)

- GND

- CAN_L

- CAN_H

J103 - SPIDER / MCU (3-Pin Micro-Fit Row)

Connection to mainboard. Galvanically isolated from 24V.

- GND

- CAN_L

- CAN_H

J_LCD - MONITOR (4-Pin Micro-Fit Row)

Power supply for USB-C monitors or HDMI displays.

- +5.2V

- +5.2V

- GND

- GND

Status LEDs ("Mouse Cinema")

The board features two labeled LEDs for quick diagnosis:

- 24V input present (fuse intact).

- 5.2V logic voltage stable (Power Good signal from TPS56637).

Software Configuration (Radxa OS / Armbian)

Since the native CAN controller is used, setup is extremely simple.

1. Enable Overlay

Add the overlay for the CAN1 controller.

Via rsetup:

Hardware -> Overlays -> Enable CAN1-M1 on GPIO3 (Pins 32/33).

Manually (/boot/extlinux/extlinux.conf):

Add rk3588-can1-m1 to the fdtoverlays line.

2. Configure Interface

Create /etc/network/interfaces.d/can0 for autostart:

allow-hotplug can0

iface can0 can static

bitrate 500000

up ip link set $IFACE txqueuelen 1024

3. Klipper Configuration

In printer.cfg:

[mcu]

canbus_uuid: <your_uuid>

# No more "serial:" entries!

Manufacturing Notes (BOM & PCB)

- PCB Specs: 4-Layer (Signal / GND / Power / Signal), 1oz copper.

- GPIO Header: A Stacking Header (Extra Tall, min. 11mm spacer height) is absolutely required to provide clearance from the CPU cooler.

- Soldering: Due to massive ground and power planes, a preheater plate (printer heated bed) or preheating in an oven (100°C) is strongly recommended.

Critical Components (LCSC):

- Buck Converter: TPS56637RPAR

- Inductor: MDA1350-2R2M (2.2µH, Isat > 15A, Shielded)

- Transceiver: SN65HVD230

- Fuse: Littelfuse 0466002.NRHF (2A, 63V Rating!)

Disclaimer:

This design works with high currents and voltages. Use at your own risk. Make sure cable cross-sections are rated for the load of your laser/hotend.

License

This project is licensed under the Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License (CC BY-NC-SA 4.0).

This means you are free to:

- Share — copy and redistribute the material in any medium or format

- Adapt — remix, transform, and build upon the material

Under the following terms:

- Attribution — You must give appropriate credit, provide a link to the license, and indicate if changes were made

- NonCommercial — You may not use the material for commercial purposes

- ShareAlike — If you remix, transform, or build upon the material, you must distribute your contributions under the same license

For the full license text, visit: https://creativecommons.org/licenses/by-nc-sa/4.0/

Note: The original documentation is in German (Readme.de.md). This English version is a translation for international users.