- Remove unused schematic files (mcu.kicad_sch, PWR.kicad_sch) - Update version numbering to semantic versioning (Rev. 0.0/0.1) - Add comprehensive changelog documentation in both languages - Create separate CHANGELOG.md and CHANGELOG.de.md files - Update PCB to Rev. 0.3 with layout optimizations - Professional 4-layer PCB design with optimal via stitching - Excellent differential pair routing for CAN-bus (< 18mm) - Superior thermal management with 19 vias at PFET drain - Strategic power plane distribution and EMI considerations - Production-ready PCB layout with best practices implementation

🔥 Laser CANbus Toolhead PCB

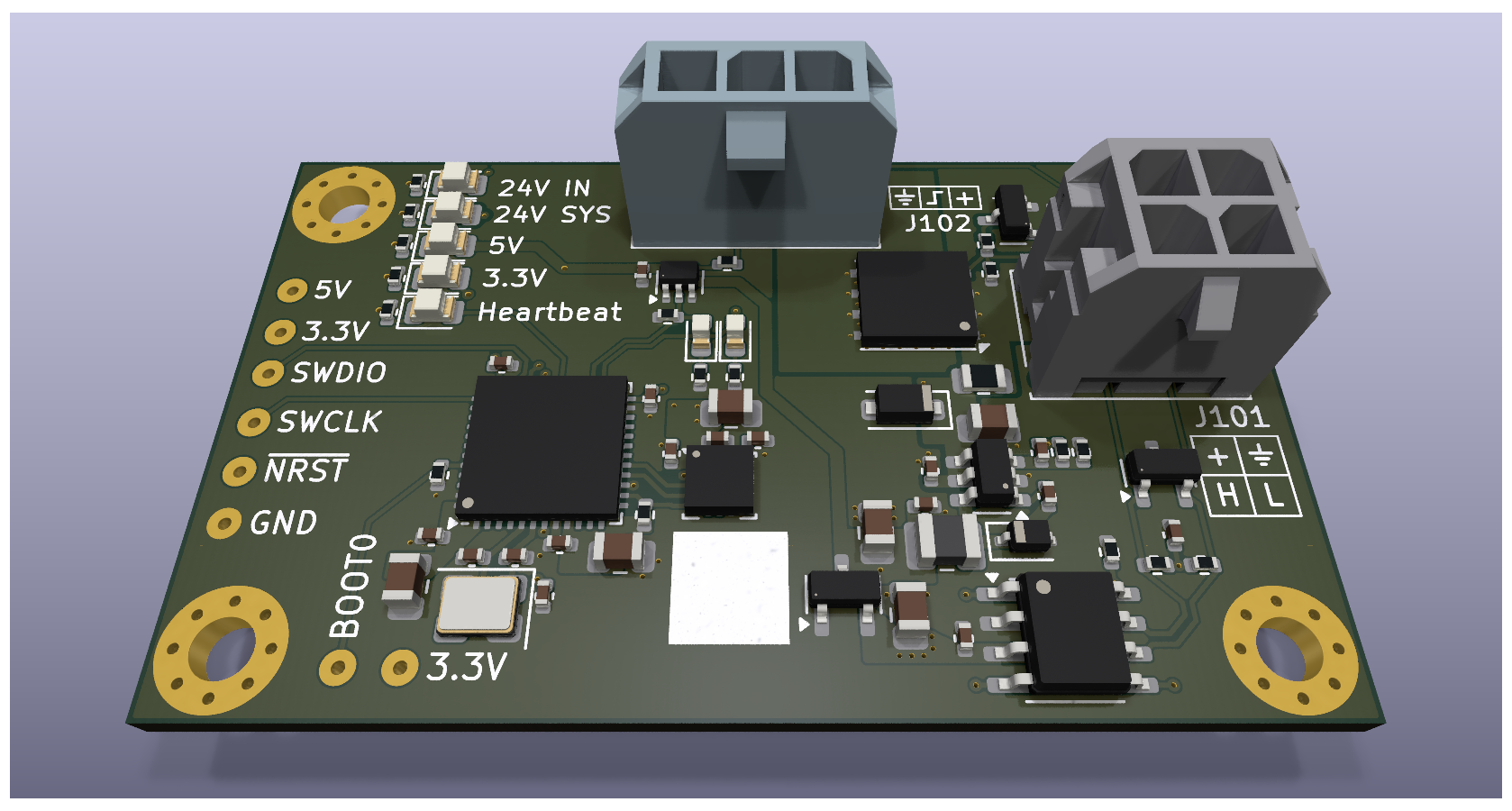

A compact, robust toolhead board for Klipper-based laser engravers and cutters (CoreXY). This board integrates power supply, laser driver logic, CAN-Bus communication, and input shaping (ICM-20602) in the smallest possible space.

📚 Contents

- 🔥 Laser CANbus Toolhead PCB

✨ Features

🧠 Microcontroller

- MCU: STM32F072CBU6 (Cortex-M0, 48MHz, CAN-capable)

- Stability: 12MHz crystal for maximum CAN-Bus stability

- Firmware: Klipper-compatible

🔗 CAN-Bus Communication

- Transceiver: SN65HVD230 with ESD protection

- Termination: Split termination via solder jumper

- Slope Control: Switchable for EMI optimization

📊 Input Shaping

- Sensor: On-board ICM-20602 accelerometer/gyroscope (SPI)

- Purpose: Klipper resonance measurement for perfect print quality

- Advantage: Better availability and modern sensor technology

⚡ Laser Power Control

- Circuit: 24V / 6A High-Side Switch (CJAC70P06 P-MOSFET, 60V rated)

- Peak Current: 8A capability

- Soft-Start: Limits inrush current (Rise-time ~1.2ms)

- Safety: Hardware pull-down prevents unwanted activation

- Limitation: Max 6A limited by Micro Fit 3.0 connector with 0.75mm² wire

🎛️ Laser Signal Control

- PWM: 5V Level-shifted via 74AHCT1G125 buffer

- Quality: Clean edges, true hardware PWM via STM32 timer

- Compatibility: Common diode lasers

🔌 Power Supply

- Input: 24V with 250mA PTC fuse and SMF24A TVS diode

- 5V Rail: MP2459 Buck converter (up to 60V input tolerant)

- 3.3V Rail: XC6206 LDO for MCU and peripherals

🚨 Diagnostics & Monitoring

- Power LEDs: 24V In, 24V Sys, 5V, 3.3V

- Status LEDs: Laser Enable, Laser PWM, Heartbeat

📋 Klipper Configuration

Basic MCU Setup

[mcu toolhead]

canbus_uuid: <your-uuid> # Find with "ls /dev/serial/by-id/*" or "~/klippy-env/bin/python ~/klipper/scripts/canbus_query.py can0"

[temperature_sensor toolhead_mcu]

sensor_type: temperature_mcu

sensor_mcu: toolhead

Input Shaping (ICM-20602)

[mpu9250]

cs_pin: toolhead:PA4

spi_bus: spi1

#axes_map: x,y,z # Configure according to your printer orientation

[resonance_tester]

accel_chip: mpu9250

probe_points:

150, 150, 20 # Adjust to your bed size

Laser Control

# Laser PWM Signal

[output_pin laser_pwm]

pin: toolhead:PB14

pwm: True

cycle_time: 0.001 # 1kHz PWM frequency

shutdown_value: 0 # Safety: laser off during emergency

# Laser Enable (optional)

[output_pin laser_enable]

pin: toolhead:PB15

value: 0

shutdown_value: 0

# Heartbeat LED (optional)

[output_pin heartbeat]

pin: toolhead:PA9

pwm: True

cycle_time: 1.0

🔌 Pinout & Connector Assignment

J101 - Power & CAN Input (Micro-Fit 3.0, 2x2, THT)

| Pin | Signal | Description |

|---|---|---|

| 1 | +24V | Main power input (High Current) |

| 2 | GND | Ground |

| 3 | CAN_H | CAN-Bus High Signal |

| 4 | CAN_L | CAN-Bus Low Signal |

J102 - Laser Output (Micro-Fit 3.0, 1x3, THT)

| Pin | Signal | Description |

|---|---|---|

| 1 | GND | Laser Ground |

| 2 | PWM | 5V PWM Signal (Level-Shifted) |

| 3 | +24V | Switched Laser Power (Soft-Start) |

Debug/Programming Header (Back Side)

| Pad | Pin | Signal | Function |

|---|---|---|---|

| 1 | - | 5V | 5V Supply (from Programmer) |

| 2 | - | 3.3V | VTref (Reference Voltage) |

| 3 | PA13 | SWDIO | Serial Wire Debug I/O |

| 4 | PA14 | SWCLK | Serial Wire Debug Clock |

| 5 | - | NRST | Reset Signal |

| 6 | - | GND | Ground |

💡 Bootloader Mode: To force the STM32 into DFU/Bootloader mode (e.g., for initial flash with Katapult), bridge the BOOT0 pad with 3.3V during power-on.

🔧 Installation & Setup

1. CAN-Bus Configuration

- Set CAN-Bus termination according to position in network

- Baud rate: 1 Mbit/s (Klipper standard)

2. Firmware Flash

- Put board into DFU mode (bridge BOOT0)

- Compile Klipper for STM32F072 with CAN support

- Flash firmware:

make flash FLASH_DEVICE=<dfu-device>

3. Find UUID

~/klippy-env/bin/python ~/klipper/scripts/canbus_query.py can0

⚠️ Safety Notes

- Laser Safety: Always wear protective eyewear

- Power Supply: Only operate with 24V DC

- Initial Setup: Slowly ramp up laser power

- Emergency: Hardware pull-down ensures safe state

🛠️ BOM (Bill of Materials) - Highlights

| Component | Value/Type | Function | Package | Order Code |

|---|---|---|---|---|

| U101 | STM32F072CBU6 | Main Microcontroller | UFQFPN-48 | STM32F072CBU6 |

| U102 | MP2459GJ-Z | Buck Converter 24V→5V | TSOT-23-8 | MP2459GJ-Z |

| U105 | SN65HVD230DR | CAN-Bus Transceiver | SOIC-8 | SN65HVD230DR |

| U106 | ICM-20602 | 6-Axis IMU (Accelerometer/Gyroscope) | LGA-16 | ICM-20602 |

| Q101 | CJAC70P06 | P-MOSFET (Laser Switch, 60V) | SOIC-8 | CJAC70P06 |

| D101 | SMF24A | TVS Diode (Overvoltage Protection) | DO-214AC | SMF24A |

| F101 | 1812L025 | PTC Fuse 250mA | 1812 | 1812L025 |

| Y101 | 12MHz | Crystal for CAN Stability | HC-49/S | 12MHz Crystal |

| J101/J102 | Micro-Fit 3.0 | THT Connectors | THT | Micro-Fit 3.0 THT |

🛠️ Technical Specifications

| Parameter | Value | Unit |

|---|---|---|

| Input Voltage | 24 ± 2 | V |

| Laser Current (max) | 4 | A |

| CAN Baud Rate | 1 | Mbit/s |

| PWM Frequency | 1 | kHz |

| Soft-Start Time | ~1.2 | ms |

| Operating Temperature | -10 to +70 | °C |

| Dimensions | TBD | mm |

📝 Changelog

Rev. 0.1

- Transistor Upgrade: Replaced MOSFET with CJAC70P06 (60V voltage rating)

- Sensor Upgrade: Changed from ADXL345 to ICM-20602 (better availability, modern 6-axis IMU)

- Connector Change: Micro Fit 3.0 connectors changed from SMD to THT mounting

- Silkscreen Enhancement: Added connector pin assignments to silkscreen for easier assembly

- Layout Improvements: Cleaned up component placement and optimized routing

- Documentation: Updated overview image to reflect current design

- BOM Update: Added component order numbers and updated production data

- Production Files: Updated assembly and production files with current components

Rev. 0.0 (Initial Release)

- Initial PCB design with STM32F072CBU6 microcontroller

- CAN-Bus communication with SN65HVD230 transceiver

- 24V/4A laser power control with AO4407A MOSFET

- ADXL345 accelerometer for input shaping

- MP2459 buck converter for power supply

📚 Additional Resources

License

This project is licensed under the Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License (CC BY-NC-SA 4.0).

This means you are free to:

- Share — copy and redistribute the material in any medium or format

- Adapt — remix, transform, and build upon the material

Under the following terms:

- Attribution — You must give appropriate credit, provide a link to the license, and indicate if changes were made

- NonCommercial — You may not use the material for commercial purposes

- ShareAlike — If you remix, transform, or build upon the material, you must distribute your contributions under the same license

For the full license text, visit: https://creativecommons.org/licenses/by-nc-sa/4.0/

Note: The original documentation is in German (README.de.md). This English version is a translation for international users.